Uplifting Craftsmen Livelihoods ︎︎︎

Servitising Traditional Textiles

Servitising Traditional Textiles

Funded By Ministry of Textiles

India, 2018

India, 2018

How might we revitalize the traditional craft sector, enhancing artisan livelihoods, aligning modern consumer needs, while preserving cultural integrity?

Textile Design, UX Research, Service Design, Product Design, Social Innovation

1. Overview & Process

The project aimed to rejuvenate a selected craft cluster by incorporating design innovations, thereby enhancing the livelihoods of the artisans. The challenge was to devise a sustainable model that would revitalize the craft's design, processes, and methodologies while preserving its cultural essence.

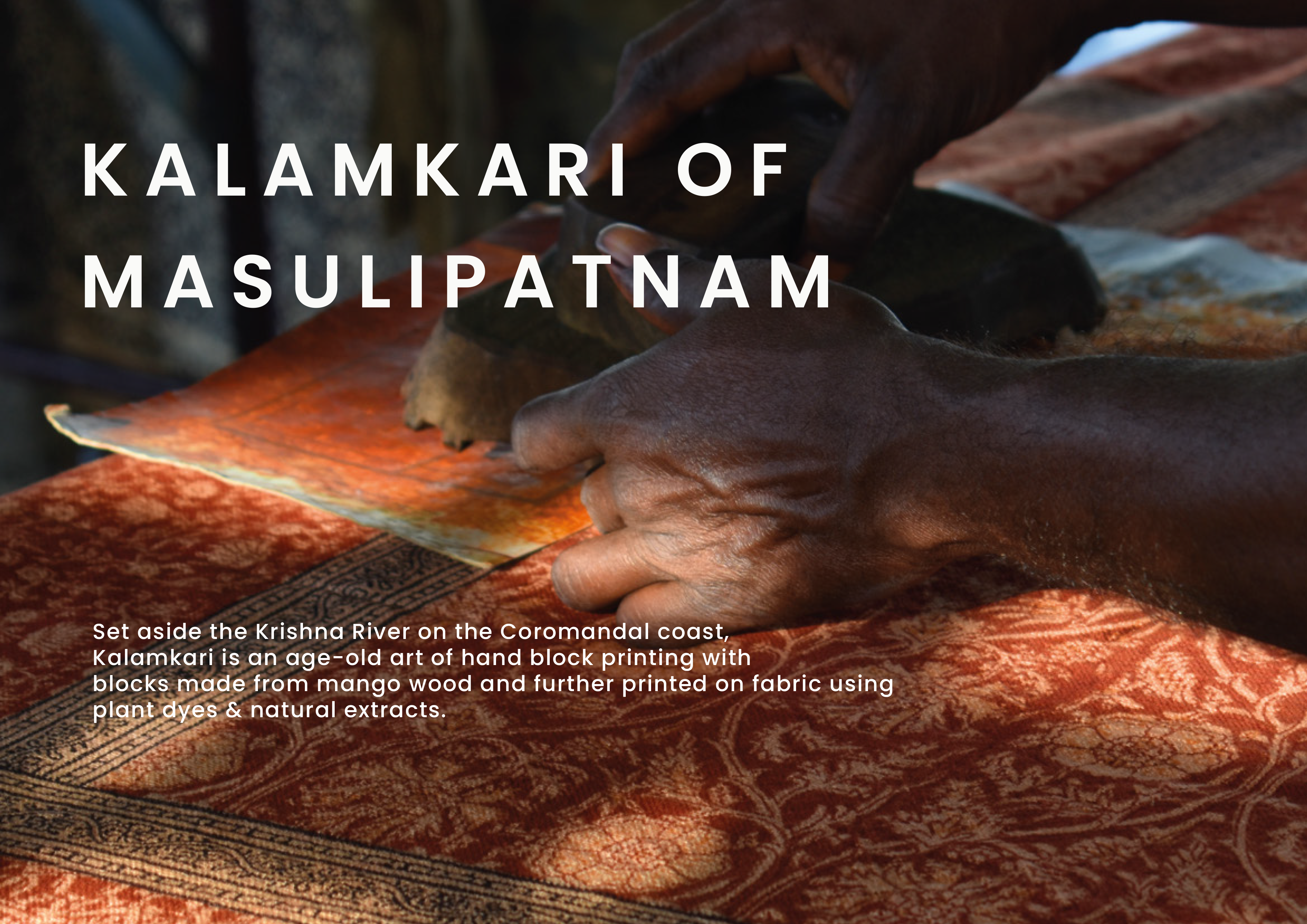

The craft of choice was, Kalamkari, which literally translates to “art made from hand.”

2. Actions Undertaken

1. Craft Research & Cultural ImmersionConducted comprehensive research and interviews, engaging in cultural immersion for deeper insights.

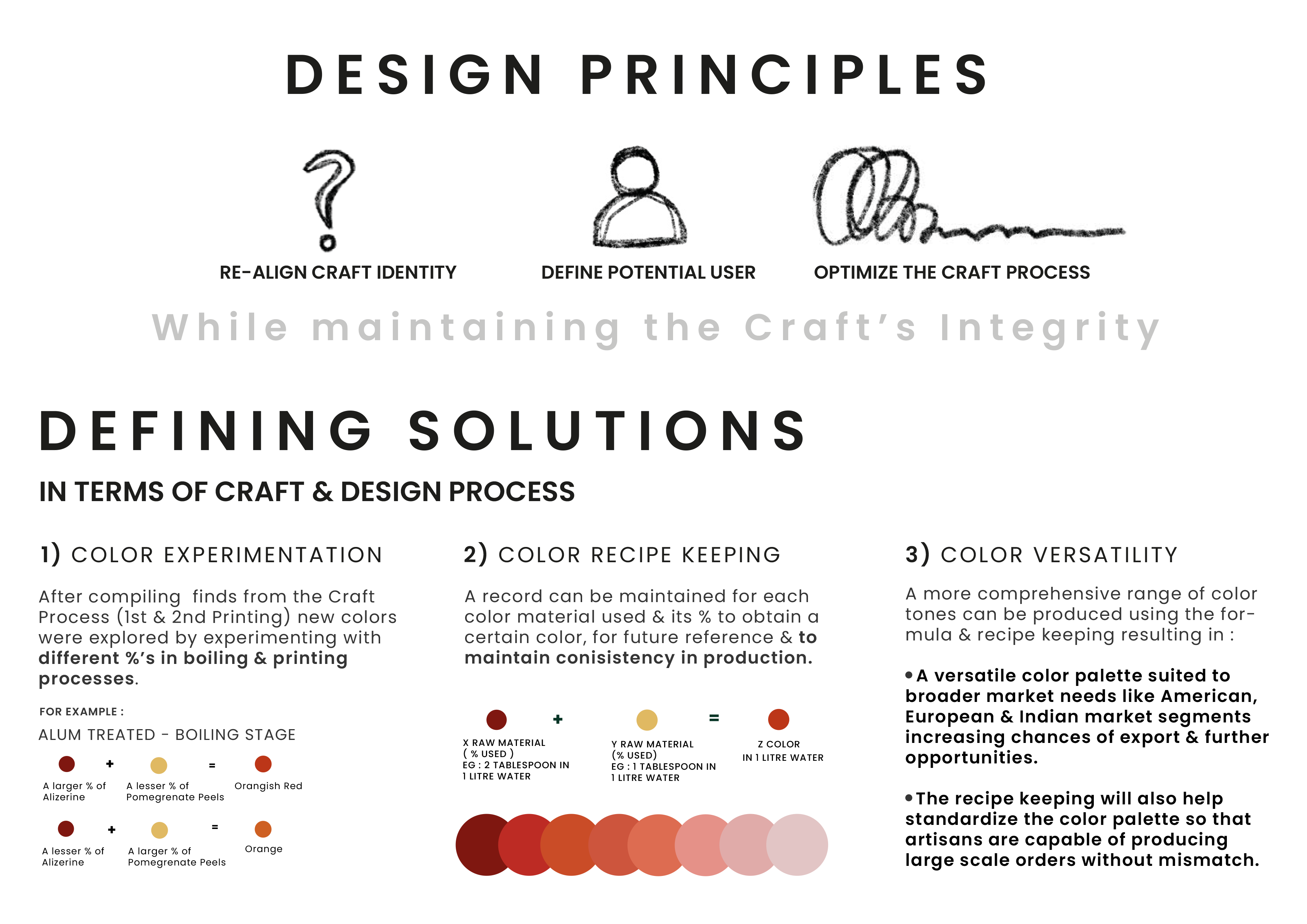

2. Redefining Craft Identity & Users Redefined the craft's identity and profiled potential users to align with market demands.

3. Traditional Process Optimization Identified and optimized areas for improvement within traditional craft processes, and conducted ritual workshops to seamlessly strengthen, yet optimise some processes.

4. Design and Product Innovation Introduced design innovations and developed new products catering to modern consumers, while maintaining the craft's essence. 5. Systemized Plan for Future Goals Developed a strategic plan outlining future goals and strategies for sustainable growth.

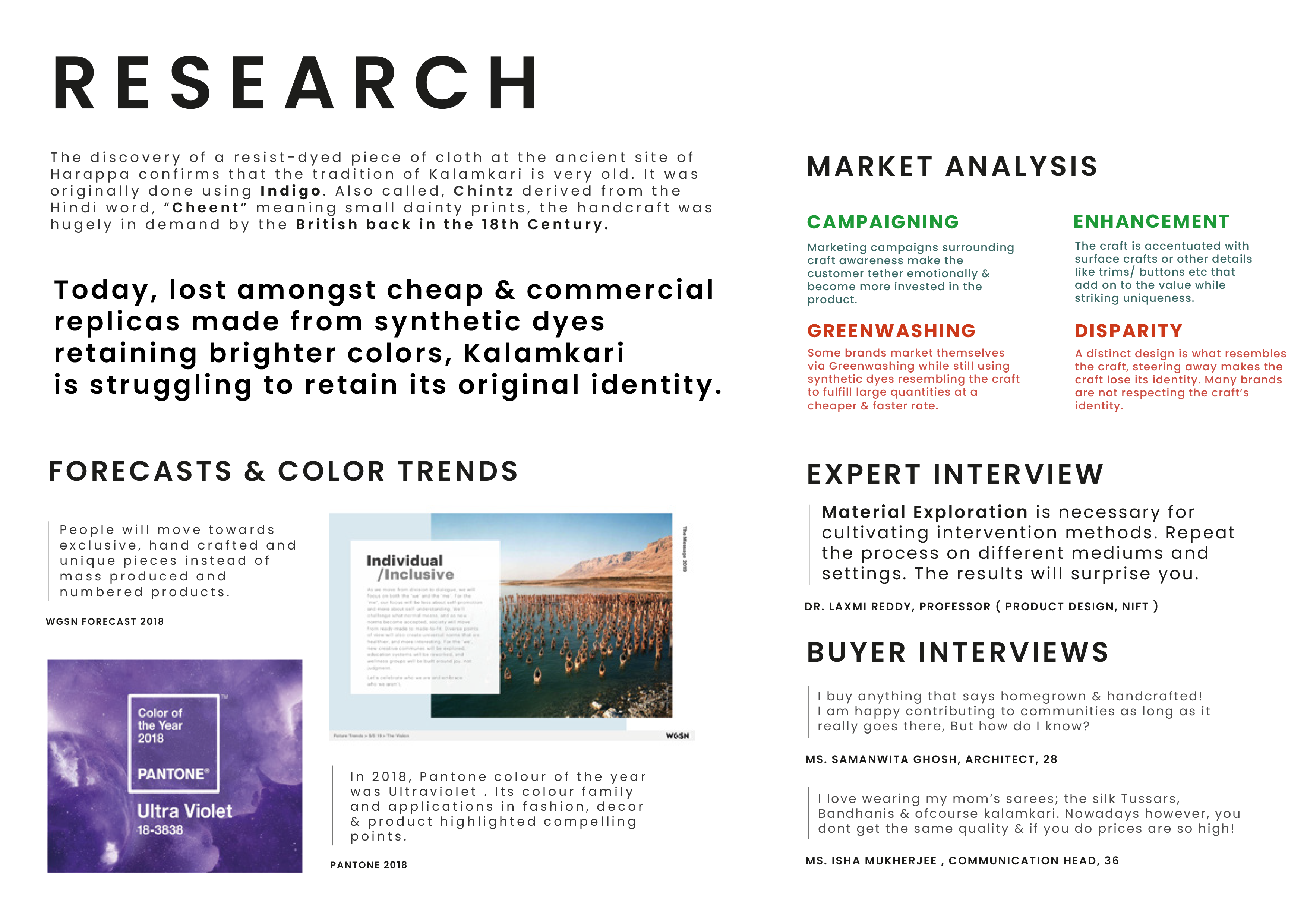

3. Primary & Secondary Research

4. Key Insights & Challenges

1. Craft Identity & Users

- Many artisans are moving away from the craft since no money or exposure hinders their livelihood.

- Mediators or brands that sell authentic Kalamkari are expensive, whereas fabric at the grassroots is cheaper.

- The gap between the final consumer and the artisan is vast.

- Users or potential users are fully aware of the craft, hence not knowing what is real or fake, making commercial synthetic replicas a cheaper and preferred option.

2. Craft Process

- Since the craft is located in countryside villages, they are not exposed to users, market trends, and vice versa.

- In order to replicate commercial and synthetic dyes since they sell faster artisans are also trying to use bright and distinctive colors of the craft like Red, Blue, Black and Yellow minimising the potential user market.

- Almost 80% of Kalamkari fabric produced is cotton and is restricted to Indian traditional wear.

- Large-scale production orders are rare since there is a 90% possibility of mismatch in sample fabric & final requirement. This happens since there is no uniform color recipe or book-keeping of percentages used in printing & boiling. Other factors like washing & drying time are also not noted as per the color obtained. It is always relied on experience or luck, resulting in a possible mismatch of orders.

- The final output is a slow process since the craft process has over a dozen steps.

5. Identifying Areas For Intervention

6. Product & Process Intervention Workshops

Over the course of several months, numerous workshops were held with craftsmen.

The objectives were to:

- Encourage comfort and familiarity with experimenting on new fabrics.

- Optimize crafting methods for efficiency.

- Introduce book-keeping practices for recording color recipes and combinations.

- Build design confidence among the artisans.

- Foster continuous experimentation while ensuring a seamless crafting process.

A quote signifies the importance of this intervention,

“ In the beginning when you asked us to use silk organza (a flimsy translucent fabric not very suitable for printing) we were very skeptical, and we thought whatever you are doing is wrong. Eventually when we carried out the process, and started rolling it out in production. We realised that this fabric is getting the most orders. Primarily because of it’s blurry output, which we see as a fault, but the customer sees it as something new.

Best part? It is still the same natural and organic process of traditional kalamlari.”

“ In the beginning when you asked us to use silk organza (a flimsy translucent fabric not very suitable for printing) we were very skeptical, and we thought whatever you are doing is wrong. Eventually when we carried out the process, and started rolling it out in production. We realised that this fabric is getting the most orders. Primarily because of it’s blurry output, which we see as a fault, but the customer sees it as something new.

Best part? It is still the same natural and organic process of traditional kalamlari.”

7. Change Drivers

Design Confidence & adaptability are the two major factors that brought a change. They saw things happen like fabric & color experimentation, which they were apprehensive of but finally embraced.

Impact

- The cluster has scaled measurably since 2018.

- They have contracts of export to Japanese & British markets where they can fulfill requirements efficiently.

- They currently have tie-ups with many brands in India that are working ethically to impact the sustainable sector.

- During COVID-19 first wave, they were also able to expand in the natural dyeing sector due to increased demands and joined hands to create all-natural, sustainable masks.

Next Steps

- The next step is inherently a step towards digitalization especially post COVID-19. A platform where the craft is constantly getting exposed to potential customers through purchase segments, social media and tailored digital strategies.

- More collaborations and stratetic partnerships with ethical SME’s allows the craft to grow and establish its target segment where even more people get acquainted with the art & show interest, ultimately increasing livelihood.